So how do brake testers work?

The brake tester’s mechanism safely measures the maximum braking force of a vehicle while the vehicle is stationary. It consists of an automated weighing system that accurately calculates the braking efficiency of the vehicle.

The brake tester consists of weighing cells on each side of the unit with a safety roller that detects whether a vehicle is present in the tester – this will also monitor any tyre slippage.

The vehicle is driven onto the brake tester with its wheels centrally located between the two larger main rollers. The brake tester is designed with a gritted surface to ensure maximum tyre protection and to simulate a common road surface. Once the vehicle details have been entered the rollers are then automatically switched on and rotate at a designated and consistent speed. The vehicle’s brakes are then applied by the operator, thus creating a force on the motor. A transducer measures the braking force of each wheel as the vehicle decelerates. During the process, the fluctuation is also measured to determine the safe balance of braking force between near and off side wheels calculating the difference in percentage form.

We have just updated our brake tester to a new MAHA testing system

This is the same system the DVTA MOT centres use for testing vehicles.

Headlight Alignment

Adjustment of headlamp systems: good to know

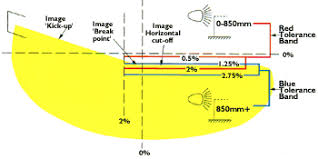

Since asymmetric light distribution appeared on the market in 1957, there have also been statutory provisions for headlamp adjustment.

Headlamps were first aimed at the so-called “10-meter wall”. That means a vehicle is driven to a distance of 10 m in front of a light-coloured wall that has certain markings on it. The headlamps are then checked or adjusted on the basis of these markings.

This has remained the statutory test method until today. It is still used particularly for checking agricultural or special vehicles. One of the disadvantages of this method is that a relatively large, light-coloured and free wall needs a corresponding amount of space. Both were, and are, not exactly often present in workshops.

These circumstances were also ultimately among the factors responsible for the development of beam setters. Such devices enable a quicker and more flexible checking of light distribution.

The following describes the measuring methods, the legal basis, and the most important stages involved in professional headlamp adjustment.